1. With the same tool you can thread blind and through holes.

2. With the same tool you can made right and left threading.

3. With the same tool you can made internal and external threading.

4. With the same tool you can made different threading of the same pitch.

5. You can intervene on the correction of the tolerance and on the compensation of the wear.

6. Absence of Chipping problems .

7. Low execution times with reduction of production’s costs.

8. Least exert pressure, ideal for least thicknesses.

9. Higher tool life in comparison to others.

10. Possibility to create special threading mills for different workmanships.

2. With the same tool you can made right and left threading.

3. With the same tool you can made internal and external threading.

4. With the same tool you can made different threading of the same pitch.

5. You can intervene on the correction of the tolerance and on the compensation of the wear.

6. Absence of Chipping problems .

7. Low execution times with reduction of production’s costs.

8. Least exert pressure, ideal for least thicknesses.

9. Higher tool life in comparison to others.

10. Possibility to create special threading mills for different workmanships.

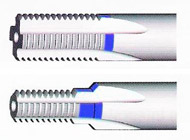

1. COOLING DUCTS

1. COOLING DUCTSFor the workmanship of passing holes, they grants a better lubrication for threading and chamfering tools, and on thrillers

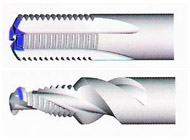

2. RECESSED NECK

2. RECESSED NECKOnly for tools that don't make chamfering operations. Suitable for longer depth threading.

3. DEBURRER TO REMOVE INCOMPLEATE THREAD

3. DEBURRER TO REMOVE INCOMPLEATE THREADMade at the end of the threading, by the shank side. It removes the incomplete thread with is burr.

4. FACE CHAMFER

4. FACE CHAMFERFace chamfer, for circular chamfering, of the thread hole and/or for precast holes. Additional cutting face, for circular face milling and/or for precasting holes

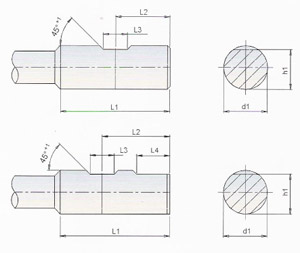

5. SHANK MODIFICATIONS.

5. SHANK MODIFICATIONS.